Ever find yourself wondering what the coins jingling in your pocket are actually made of? It’s a common misconception that they’re still precious metals like gold or silver. In reality, modern UK coins are crafted from very specific metal alloys—copper-plated steel for pennies and two-pence pieces, and a cupro-nickel blend for the 'silver' coins.

The Metals Inside Modern UK Coins

This shift away from precious metals wasn't some happy accident; it was a very deliberate choice driven by simple economics and practicality. It helps to think of modern currency as a finely-tuned machine. For it to work smoothly, the materials need to be cost-effective, tough enough for daily handling, and tricky to counterfeit.

This shift away from precious metals wasn't some happy accident; it was a very deliberate choice driven by simple economics and practicality. It helps to think of modern currency as a finely-tuned machine. For it to work smoothly, the materials need to be cost-effective, tough enough for daily handling, and tricky to counterfeit.

The Royal Mint has honed in on specific alloys that perfectly meet these demands. The copper-plated steel in our 1p and 2p coins gives them that traditional copper look, but at a tiny fraction of what solid bronze would cost. Likewise, the cupro-nickel used for 5p, 10p, 20p, and 50p coins offers a convincing silver-like appearance and excellent resistance to wear and tear, all without the hefty price tag of actual silver.

Why Not Precious Metals Anymore?

If you look back through the history of UK coinage, you’ll find plenty of examples where currency was made from precious metals. Early British coins from the Anglo-Saxon period, for instance, were typically silver or gold. This directly tied their value to the metal they contained. However, the high cost and unpredictable supply of these metals often caused economic wobbles and debasement—where the purity of the metal was secretly reduced. You can explore more on the evolution of British coins on Britannica.com.

This colourful history really explains the modern approach. By using base metal alloys, we ensure a coin's value is its face value, not what you could get for melting it down for scrap.

The core principle of modern coinage is stability. The materials are chosen to ensure the cost of making a coin is significantly less than its monetary value, preventing the temptation to melt them down for profit.

This modern blueprint is a fascinating blend of metallurgy and economic strategy, all designed to create a reliable and economical currency system. The bimetallic £1 and £2 coins take this a step further, combining different alloys not just for their good looks but also as an advanced security feature.

Composition of Current UK Circulating Coins

To give you a clearer picture, here’s a breakdown of what each of the coins we use today is made from.

| Coin | Metal Composition |

|---|---|

| 1p | Copper-plated steel |

| 2p | Copper-plated steel |

| 5p | Nickel-plated steel |

| 10p | Nickel-plated steel |

| 20p | Cupro-nickel (84% copper, 16% nickel) |

| 50p | Cupro-nickel (75% copper, 25% nickel) |

| £1 | Outer: Nickel-brass (76% copper, 20% zinc, 4% nickel). Inner: Nickel-plated alloy |

| £2 | Outer: Nickel-brass (76% copper, 20% zinc, 4% nickel). Inner: Cupro-nickel (75% copper, 25% nickel) |

As you can see, it's a carefully considered mix of materials, each chosen for its specific properties of durability, cost, and security.

A Journey Through Britain’s Coinage History

To really get to grips with what coins are made of today, you first have to take a look back. For centuries, a coin wasn't just a symbol of value—its worth was literally in the metal it was made from. The story of Britain's money is a fascinating tale of moving from this tangible, intrinsic value to the practical, modern alloys we use now.

This journey starts with the Anglo-Saxons, who minted silver pennies that were quite literally worth their weight in silver. For hundreds of years, silver, and later gold, was the very foundation of the nation’s currency. When you held a coin, you were holding a real piece of wealth. But this direct link between metal and money made the whole economy vulnerable to the changing prices and availability of these precious materials.

The Great Debasement and Silver's Decline

A huge turning point came during the reign of Henry VIII. Under immense financial pressure, he began what history now calls the 'Great Debasement'. He ordered the purity of silver in coins to be drastically cut, bulking them out with cheaper copper. It didn't take long for people to realise their money was worth less, sparking widespread distrust and economic chaos. It was a powerful, real-world lesson in what happens when you tamper with a currency's integrity.

The link to precious metals kept weakening over the centuries that followed, often sped up by the massive costs of war. Some of the most significant shifts include:

- 1920: After the immense economic strain of the First World War, the silver content in coins was slashed from the traditional 92.5% (Sterling silver) to just 50%.

- 1947: In the aftermath of the Second World War, the last traces of silver were removed from circulating coins entirely. It was replaced by the much more affordable cupro-nickel alloy.

The removal of silver from coinage in 1947 truly marked the end of an era. From that moment on, the value of UK coins was set by government decree, not by the material they were minted from.

From Precious Metals to Practical Alloys

This slow move away from silver and gold wasn't just about saving money; it was about building a stable and dependable currency for a modern economy. Every change in a coin's makeup reflects a specific moment in British history, telling a story of economic challenges and clever adaptation. The very metals in our pockets are a direct result of these historical pressures, from royal whims to the fallout from global conflicts.

If you're keen to explore this fascinating evolution, you can take a more detailed look at the brief history of British coins and see just how each era left its metallic mark.

How Decimalisation Reshaped UK Coin Materials

The slow move away from precious metals really set the scene for one of the biggest moments in the UK's currency history: Decimal Day. On 15th February 1971, the ancient system of pounds, shillings, and pence that had been used for centuries was swept away, replaced by a much simpler decimal system. But this was more than a simple change in how we count our change; it was a monumental feat of logistics and material science that completely redefined what UK coins are made of.

Just try to imagine the sheer scale of the task. The Royal Mint had to design, mint, and get an entirely new set of coins into the hands of the public to replace the old currency. This massive overhaul was the perfect chance to roll out modern, cost-effective metal alloys for all the new coins, finally leaving the expensive and impractical materials of the past behind. The new coins had to be tough, easy to tell apart, and cheap enough to produce by the billion.

Introducing the New Bronze Penny

The new 1p and 2p coins are a perfect example of this shift in thinking. Instead of using the costly metals found in older coins, the Royal Mint opted for a specific bronze alloy for its new "copper" coins. It was a carefully calculated decision, balancing looks, durability, and cost to create a coin that could stand up to decades of use.

The amount they had to produce was simply staggering. To get the nation ready for the big switch, the Royal Mint produced over 1.5 billion 1p coins alone (1,521,666,250, to be precise) between 1968 and the end of 1971. These first decimal pennies were struck from a bronze alloy of 97% copper, 2.5% zinc, and 0.5% tin at the brand-new Royal Mint facility in Llantrisant, South Wales. You can find out more about this iconic coin's story from the original British decimal penny page on Wikipedia).

Decimalisation wasn't just about changing numbers; it was a fundamental reinvention of the physical currency. It forced a national re-evaluation of what a coin should be made of, prioritising practicality and economic sense over historical tradition.

A New Era for Coin Composition

The new "silver" coins, the 5p and 10p, had actually been introduced a few years earlier, matching the size of the old shilling and florin to ease the transition. Their creation cemented cupro-nickel as the new standard for silver-coloured coins. This hardy alloy of copper and nickel gave the coins their familiar silver look and the toughness needed for daily life, all without the huge cost of actual silver.

This single event laid the foundation for the coin materials we still see in our pockets today. The choices made in the run-up to 1971—settling on specific bronze and cupro-nickel alloys—were all driven by the need to build a modern, stable, and affordable currency system from the ground up. It was a complete rethink of how our money was made, linking one day in history to decades of currency evolution.

From Raw Metal to Pocket Change at the Royal Mint

Have you ever stopped to think about how a simple piece of metal becomes the perfectly detailed coin in your pocket? The whole process is a remarkable fusion of raw industrial power and incredible precision, a craft that has been honed over centuries by institutions like the Royal Mint. It's less of an old-world workshop and more of a high-speed, modern production line.

The journey from a chunk of metal to finished pocket change is a meticulously controlled sequence of events. It all starts with melting and blending metal alloys to incredibly precise standards. This ensures every coin has the right colour, weight, and the durability to last for decades. This molten metal isn’t poured into tiny coin moulds, though. Instead, it’s cast into huge slabs, which are then rolled out into massive, gleaming strips of a specific thickness.

Blanks from Metal Strips

You can think of it a bit like rolling out dough, but with enormous industrial machines that can handle tonnes of metal at a time. These long metal strips are then fed into what’s known as a blanking press. This powerful machine acts like a giant cookie cutter, punching out thousands of plain, featureless discs at incredible speeds. These discs are called blanks, or sometimes planchets.

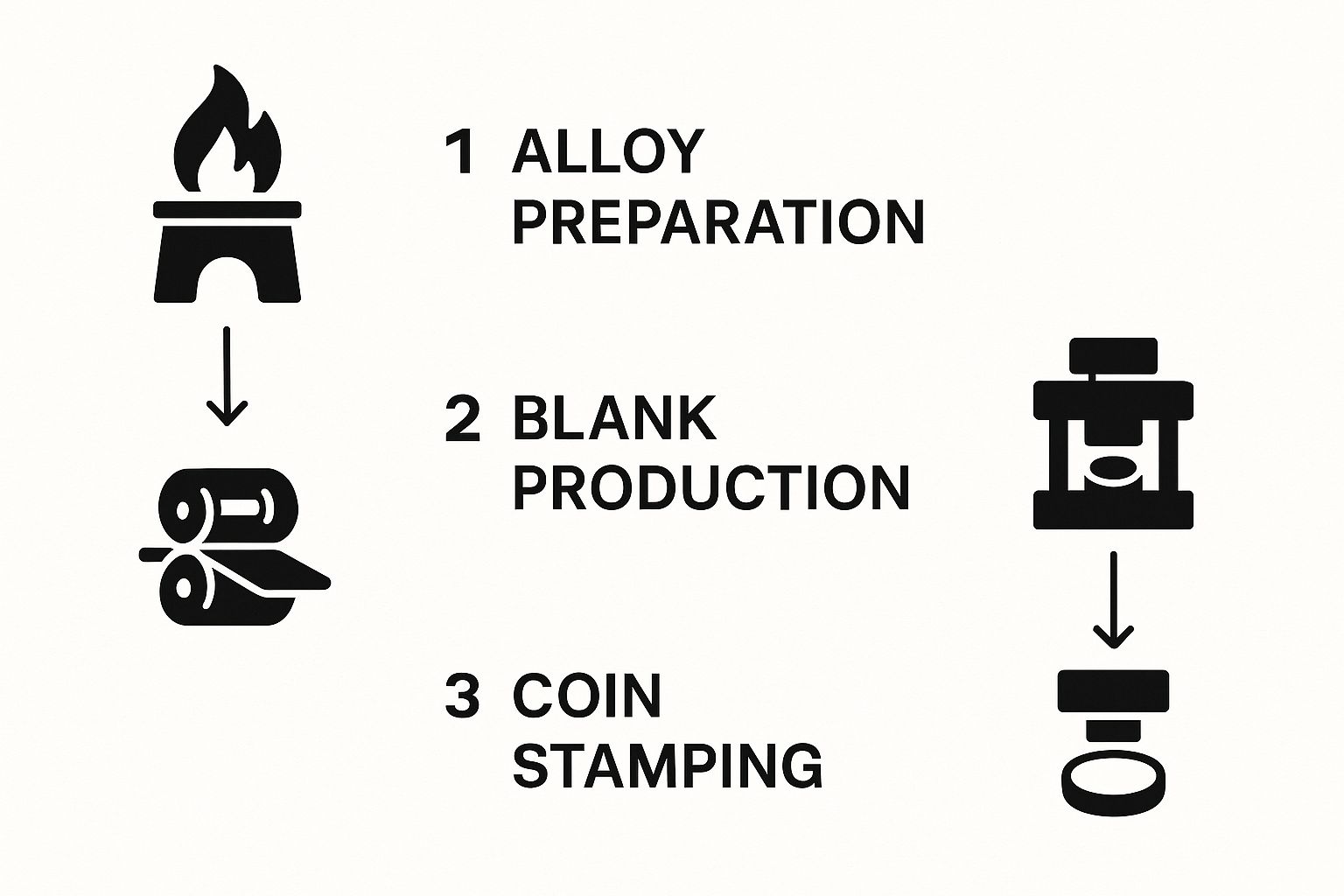

Next, the blanks are put through a process called 'rimming' or 'upsetting'. This clever step creates the raised edge you see on most coins. That rim is more important than you might think; it protects the coin's design from everyday wear and tear and also makes the coins much easier to stack. The infographic below gives a great visual summary of this core process.

As you can see, creating a coin follows a very clear and logical path, from preparing the raw alloy right through to the final strike. It’s this structured method that guarantees consistency and efficiency, allowing for the minting of billions of identical coins.

The Final Strike

Now for the magic moment: the striking. Each prepared blank is fed into a coining press and held firmly in place by a collar. Then, with an immense amount of force—often over 60 tonnes—two dies made of hardened steel strike the blank at exactly the same time. One die carries the 'heads' (obverse) design, and the other has the 'tails' (reverse).

In that single, powerful instant, the plain disc is completely transformed. The intricate designs are stamped onto its surfaces, and the collar often creates that reeded or milled edge you can feel on coins like a 10p.

This happens at a breathtaking pace, with modern presses capable of striking up to 750 coins per minute. After they're made, the new coins are rigorously inspected for any flaws before being counted, bagged, and sent out into the world. It’s this commitment to quality that has earned the Royal Mint a global reputation. To find out more, you can read about the worldwide reach of the Royal Mint and the many countries it supplies. The journey shows that what coins are made of is only the beginning of their fascinating story.

Why Pennies and Two-Pence Pieces Switched to Steel

The story behind modern UK coins has a fascinating twist, and it centres on the humble penny and two-pence piece. For years after decimalisation, these coins were struck from a bronze alloy, giving them that classic copper look we all know. But behind the scenes, a simple economic drama was brewing that would force a huge change.

It all boiled down to a classic problem: the coins were becoming worth more as scrap metal than as actual currency. By the early 1990s, the world price of copper had shot up so much that the metal value of the bronze 1p and 2p coins was creeping dangerously close to—and sometimes even over—their face value. This created a massive risk. What was to stop people from just melting the coins down and selling the metal for a tidy profit?

The Economic Squeeze

When a coin's inherent metal value gets higher than its monetary value, it puts the whole currency system at risk. The Royal Mint was facing a serious headache. If they kept making bronze coins, they would lose money on every single one they minted. At the same time, they’d be encouraging people to destroy existing currency for its raw materials. A change wasn't just on the cards; it was absolutely essential.

This situation led to one of the biggest shifts in modern UK coinage. Between 1971 and September 1992, the British one pence piece was made from a bronze alloy of 97% copper, 2.5% zinc, and 0.5% tin. But as metal costs spiralled, the Royal Mint pivoted to a much more sustainable solution in 1992: a steel core electroplated with a thin layer of copper. This brilliant move allowed them to produce millions of coins at a far lower cost. You can dive into the detailed mintage figures over on the Royal Mint's official website.

The 1992 switch to copper-plated steel was a masterclass in economic problem-solving. It kept the traditional look of Britain's "copper" coins while making sure they remained cheap enough to produce for decades.

A Practical and Lasting Fix

This new composition was a clever fix. The steel core provided the bulk of the coin very cheaply, while the thin copper plating gave it the familiar reddish-brown colour the public was used to. As a side effect, this change also made the newer coins magnetic—a simple test you can do at home to tell post-1992 "coppers" apart from their older bronze cousins.

This whole episode is a perfect real-world example of how global market forces can directly change the money in your pocket. It just goes to show that what coins are made of isn't a fixed fact, but an ever-changing equation. It's a constant balancing act between durability, security, and plain old economic common sense. The humble penny’s story is a powerful reminder that our currency is always adapting.

The Special Metals in Commemorative and Bullion Coins

While the coins in our everyday change are made from practical, cost-effective alloys, there's another world of coinage where precious metals still reign supreme. This is the realm of commemorative and bullion coins, which are crafted not for circulation, but for collectors and investors.

Unlike a standard 50p piece, these special issues are what coins are made of when value, rarity, and artistry are the primary goals.

Think of the famous Britannia series from the Royal Mint. While you might find a standard Britannia 50p in your change, the bullion versions are struck in materials like .999 fine silver or even 24-carat gold. These aren't designed for buying groceries; they're created as a way to own a tangible piece of precious metal, valued for its weight and purity.

Intrinsic Value vs Face Value

This brings us to a crucial concept in numismatics: the difference between face value and intrinsic value. The coins we use daily have a low intrinsic value—their worth comes from the number stamped on them by the government. A 10p coin is worth 10p simply because we all agree it is.

For commemorative and bullion coins, the opposite is true.

These coins often have a nominal face value—a £2 or £100 denomination, for example—but their real worth is tied directly to the precious metal they contain. This is their intrinsic value, which fluctuates with the global market prices of gold and silver.

Their value isn't just in the metal, though. It also comes from their artistry and, most importantly, their rarity. A limited-edition proof coin can be far more valuable than its metal content alone, much like how a rare stamp is worth more than the paper it's printed on.

For example, understanding what makes a specific coin valuable, such as its mintage numbers and condition, is key to appreciating its worth. This principle applies even to a supposedly common coin; you can learn more by exploring what makes the most valuable British one penny coin so elusive. These special issues are truly where modern metallurgy meets high art and investment.

A Few Common Questions About Coin Materials

As we've explored what coins are made of, a few common questions tend to pop up time and again. Let's tackle some of the most frequent curiosities people have about the metal in their pocket change, building on what we've already covered.

You’ve probably noticed that modern 1p and 2p coins will happily stick to a magnet, while older ones won't. This isn't your imagination! The switch happened in 1992. Before then, our "coppers" were made from a non-magnetic bronze alloy. Now, they have a steel core (which is magnetic) coated with a thin layer of copper.

Another point of fascination is the two-tone design of our £1 and £2 coins. This bimetallic feature isn't just for show; it’s actually a clever security measure. By combining two distinct alloys—a nickel-brass outer ring and a cupro-nickel or nickel-plated inner disc—the coins become much more difficult and costly for counterfeiters to copy.

Identifying Old Silver and Looking to the Future

So, how can you spot if an old British coin is genuine silver? It's all about the date. As a rule of thumb, any British "silver" coin minted before 1947 has real silver content. Coins stamped between 1920 and 1946 are 50% silver, while their older counterparts, from before 1920, are made of 92.5% Sterling silver. Beyond the date, they often have a brighter, almost whiter look and give off a distinct high-pitched ring when dropped, unlike the duller appearance of modern cupro-nickel.

A question I often hear is whether the materials in our coins will change again. The answer is almost certainly yes. As metal prices shift and new security technologies are developed, The Royal Mint will continue to adapt. It's a constant balancing act to ensure our currency is both secure and economical to produce.

This cycle of change is really at the heart of coinage history. The metals used in our money are a direct reflection of the economy and technology of the time, making every coin in your pocket a small part of a much larger, ever-evolving story of innovation.

For collectors and enthusiasts keen to dive deeper into the rich history and diverse materials of currency from Britain and beyond, Cavalier Coins Ltd offers an extensive selection. Discover rare pieces, build your collection, and join a community of fellow numismatists at https://www.cavaliercoins.com.