Long before a coin ever jingles in your pocket, its story begins not with metal and machinery, but with a strategic government decision. The real answer to how are coins made starts with careful economic forecasting to ensure just the right amount of money enters circulation to meet public demand.

The Journey from Treasury Vault to Your Wallet

Every single coin starts its life as an idea, a direct response to the nation's need for physical currency. In the UK, this is a finely tuned dance between His Majesty’s Treasury and The Royal Mint. The Treasury holds the ultimate authority, giving the official green light for any new coin production based on complex economic signals.

This is far from a random act. The Royal Mint is constantly taking the pulse of the country's currency flow. They collect data from major banks and Post Offices to get a clear picture of how many coins are being used, saved, or simply lost down the back of the sofa. This intelligence allows them to forecast future demand with impressive accuracy.

When their models indicate a need for more pennies, pounds, or any other denomination, they present their case to the Treasury.

The core responsibility for managing the nation's currency lies with The Royal Mint, which is entrusted by HM Treasury to strike the official coinage of the United Kingdom. This crucial partnership ensures the money supply directly reflects the genuine needs of the economy.

From Mandate to Mintage

Once the Treasury gives its formal approval, The Royal Mint receives its production orders. These directives are incredibly specific, outlining the exact quantity of each coin denomination required to top up the national stock. This is the moment the entire minting operation kicks into gear—it's the "why" behind every new coin that will eventually land in your hands.

This whole process is designed to maintain a stable and functional cash system. Think of it in these key stages:

- Demand Forecasting: The Royal Mint meticulously analyses data from banks and retailers to predict exactly how many new coins are needed.

- Government Approval: HM Treasury reviews these forecasts and officially commissions the required mintage.

- Production Planning: With the order confirmed, The Royal Mint then schedules the production runs for the necessary denominations.

The sheer scale of this operation is staggering. As of October 2024, there were approximately 27 billion coins in circulation across the UK, every single one of which started its life this way. You can dig into the detailed mintage figures to really grasp the vast number of coins produced by The Royal Mint over the years.

To simplify this complex process, here’s a quick overview of how a UK coin goes from a government requirement to public currency.

The UK Coin Lifecycle at a Glance

| Stage | Responsible Body | Primary Function |

|---|---|---|

| Forecasting & Proposal | The Royal Mint | Analyses currency usage data to predict future demand and proposes new mintage numbers. |

| Authorisation | HM Treasury | Reviews the proposal and gives the official government approval to produce new coins. |

| Production Order | The Royal Mint | Receives the official mandate and schedules the minting of specific denominations. |

| Minting | The Royal Mint | Manufactures the physical coins according to the authorised quantities. |

| Distribution | Banks & Cash Centres | Receive the newly minted coins and distribute them into the national financial system. |

| Circulation | The Public | Coins enter everyday use in shops, vending machines, and personal transactions. |

This table neatly summarises the organised journey each coin takes, highlighting the essential collaboration between the government and the mint.

Distribution to the Public

After being struck, counted, and securely bagged, these new coins don't go straight to your local shop. Their next stop is a network of cash-handling centres and banks across the country. From these central hubs, they are distributed throughout the UK's financial system, finally making their way into cash registers, vending machines, and, eventually, your wallet.

This intricate supply chain is a testament to the highly organised system behind the coins we often take for granted. It's worth remembering that The Royal Mint's role extends far beyond British shores; it also produces currency for many other nations, showcasing the worldwide reach of The Royal Mint and its renowned expertise.

Designing a Nation's Story in Metal

A coin is so much more than a simple piece of currency. Think of it as a miniature, metallic canvas that tells a nation’s story. This is the stage where raw metal gets its soul, transforming a plain disc into a symbol of heritage and history. The entire design process is a careful dance between artistic vision and serious technical precision—a journey from a fleeting idea to a perfect digital blueprint.

A coin is so much more than a simple piece of currency. Think of it as a miniature, metallic canvas that tells a nation’s story. This is the stage where raw metal gets its soul, transforming a plain disc into a symbol of heritage and history. The entire design process is a careful dance between artistic vision and serious technical precision—a journey from a fleeting idea to a perfect digital blueprint.

Every design, naturally, starts with a theme. For the standard coins rattling around in our pockets, this is usually a continuation of established national symbols. But for commemorative pieces, the process is far more exciting. The Royal Mint Advisory Committee, an independent panel of experts, steps in to recommend themes and review designs, making sure they meet the highest standards of quality and cultural meaning.

From Concept Sketch to Digital Sculpture

Once a theme is green-lit, artists and designers are invited to submit their interpretations. The first glimmers of a new coin often begin life as simple, hand-drawn sketches. Artists explore different ways to capture the spirit of the person, event, or anniversary being celebrated. It’s a very competitive field, and the winning design is chosen not just for its beauty, but for how well it works within the tiny, circular world of a coin.

The selected sketch then lands on the desks of The Royal Mint’s incredibly skilled engravers and designers. Using a mix of traditional plaster modelling and cutting-edge digital sculpting software, they translate the flat, 2D artwork into a detailed 3D model. This is where the real magic happens.

Every single detail has to be flawless. The portrait of the monarch—currently the official effigy of King Charles III—demands immense skill to get just right. The texture of a uniform, the look in an eye, the specific curve of a letter—all must be meticulously crafted. The final design needs to be both visually striking and technically robust enough for striking.

Commemorating National Milestones

The cultural weight of this design work really shines through in special commemorative releases. The Royal Mint, for instance, has a long history of celebrating British heritage with uniquely themed coins. The planned releases for 2025 include two new 50p coins honouring the 60th anniversary of the Red Arrows' first display and recognising key figures from World War II. You can discover more about the upcoming 2025 coin designs and the incredible stories they tell.

This whole process ensures that when we ask how are coins made, the answer goes far beyond industrial machinery. It’s about the thoughtful consideration of:

- Historical Significance: Portraying the event or person with accuracy and deep respect.

- Artistic Interpretation: Giving the artist space to bring their unique style and vision to the theme.

- Technical Feasibility: Ensuring the intricate design can be perfectly stamped millions of times over during the striking process.

In the end, this digital model becomes the master tool path. It guides a high-precision cutting machine to engrave the design onto a steel master die, which is the next vital step in the coin's journey from concept to collection.

Preparing the Blanks for Striking

Every coin begins its life as a simple, perfectly formed metal disc. We call this a blank—or, to use the more technical term, a planchet. Before any recognisable design can be stamped onto it, this humble piece of metal has to be prepared with incredible precision. The quality of these blanks is absolutely foundational; the entire coining process depends on transforming vast metal sheets into these flawless building blocks.

The journey starts with enormous coils of metal, some weighing several tonnes. These are carefully fed into a massive blanking press, which acts like a gigantic, industrial-scale hole punch. With each powerful blow, it stamps out thousands of perfectly round discs from the metal sheet at incredible speed.

What’s left behind is a sheet of metal that looks a bit like a web. This leftover material isn’t wasted, though—it’s all collected and recycled for future use, making the process surprisingly efficient.

From Raw Disc to Prepared Planchet

Once they’re punched out, the raw blanks aren’t quite ready. They have rough edges and are far too hard to properly take on the design from a coining press.

To sort this out, they go through a heat treatment process called annealing. The blanks are sent through a furnace heated to over 850°C. This extreme heat softens the metal, making it more malleable and ready to receive the intricate details of the coin’s design.

After their fiery trip through the furnace, the blanks are immediately quenched in a chemical solution to cool them down quickly. This is followed by a thorough cleaning and polishing, often by tumbling them in a large barrel with special polishing media until they are gleaming and blemish-free. The exact metal used varies a lot, which you can learn more about in our guide on what coins are made of.

The choice of metal for a circulating coin is all about finding a balance between durability and cost. In the UK, you’ll find a few different compositions:

- 1p and 2p Coins: These are made from copper-plated steel.

- 5p and 10p Coins: These are made from nickel-plated steel.

- 20p and 50p Coins: These use a cupro-nickel alloy (a mix of copper and nickel).

- £1 Coin: This is also a bimetallic coin, the outer ring is a nickel-brass alloy, whilst the inner is a nickel-plated alloy.

This variety isn't just for show; it's a key part of the minting process, ensuring each denomination has the right properties for a long life in circulation.

The Crucial Upsetting Stage

The final step before striking is arguably one of the most important for a collector to understand. The polished, softened blanks are fed into an upsetting mill.

This machine has a specially designed grooved channel that is just a fraction smaller than the blank’s diameter. As the blank is forced through this tight channel, the pressure raises a distinctive, uniform rim around its edge.

This raised rim is absolutely essential. It does more than just protect the coin's main design from wear and tear; it also helps ensure the metal flows correctly and evenly when the coin is struck. Without this rim, the immense pressure from the dies would cause the metal to spread out unevenly, leading to a weak or incomplete strike.

Now, at last, the planchets are fully prepared. They're clean, soft, and have that all-important raised rim. They are no longer just blanks; they are ready for the coining press, where they will finally be transformed from anonymous metal discs into the coins we all recognise.

The Moment of Creation: Inside the Coining Press

This is it. The dramatic climax of the entire coin-making journey. In a single, fleeting moment, a polished, anonymous metal disc becomes a piece of recognisable currency. Every careful step of preparing the blank culminates right here, in the heart of a high-speed coining press.

At the core of the press are the two master dies. These aren't just any pieces of metal; they are incredibly hard steel cylinders, each expertly engraved with a negative, or inverted, image of the coin's design. The obverse die—what we’d call the "heads" side, usually with the monarch's portrait—is fixed in the lower position. The reverse die, for the "tails" side, is fitted into the upper, moving part of the machine.

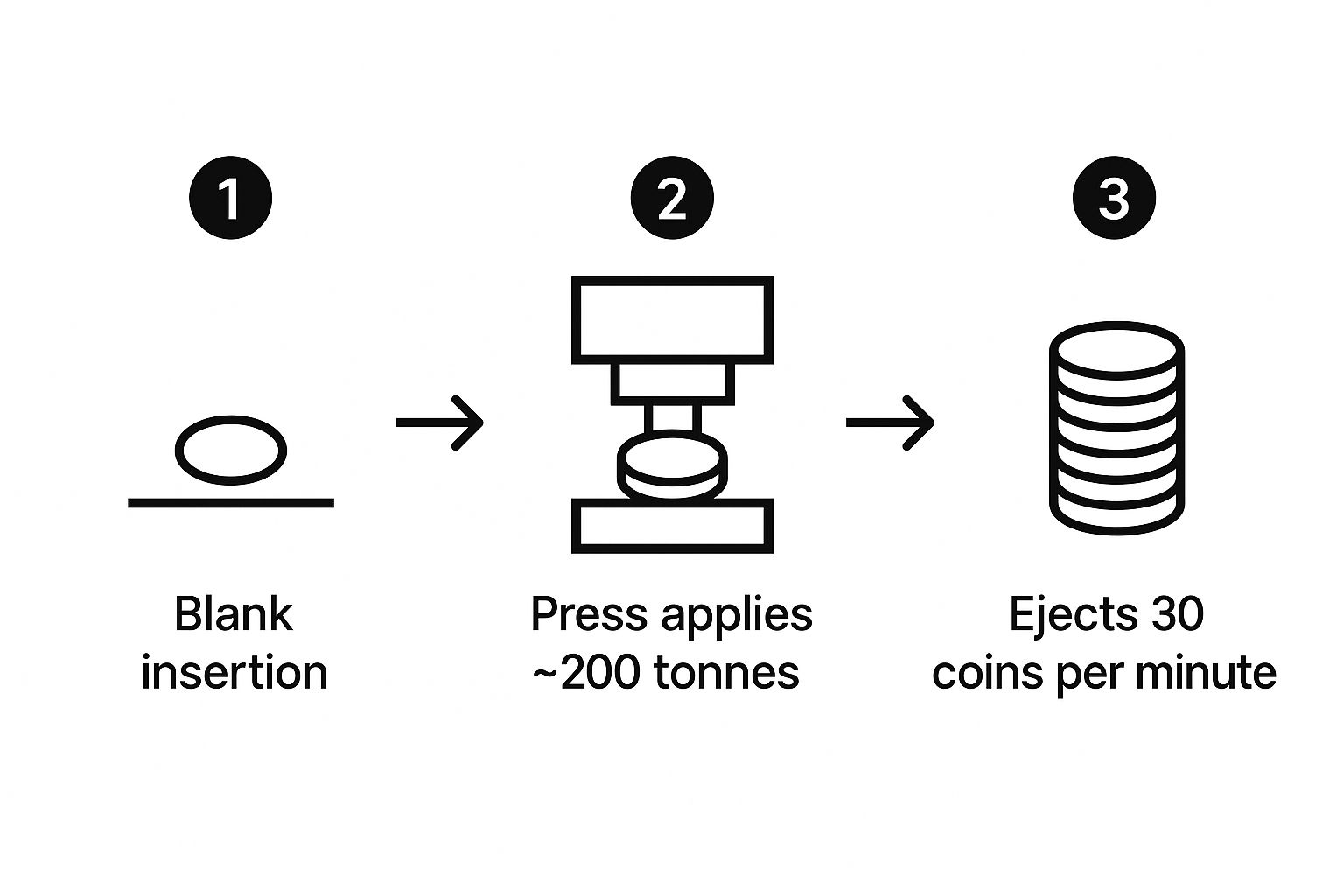

A prepared blank is automatically fed into the sweet spot between these two dies. Then, in one powerful, violent motion, the press slams them together with hundreds of tonnes of force. For a standard UK coin, this can be up to 200 tonnes. To put that in perspective, imagine the weight of 33 African elephants, all focused on that tiny metal surface.

The Physics of the Strike

That immense pressure forces the softer, more malleable metal of the blank to flow like a liquid into every microscopic detail of the die's design. This isn't just about stamping an image on top. It’s a true process of cold forging, where the metal is completely reshaped under extreme force. This is how all the intricate details we see, from the tiny letters to the fine lines in a portrait, are born in a fraction of a second.

This image gives you a simplified idea of how the coining press works, from feeding the blank in to ejecting the finished coin.

What's really highlighted here is the incredible efficiency of a modern mint. A single press can apply that mind-boggling force and spit out finished coins at a blistering pace.

While all this is happening, a third piece joins the action: the collar die. This is a simple ring that wraps around the blank during the strike. As the coin is squeezed, the metal has to go somewhere, so it expands outwards. It presses hard against the collar, which imprints the coin’s edge. This is how you get a reeded edge, like on a 10p, or just a plain, smooth edge.

Circulation Coins Versus Collector Proofs

For collectors, this is where things get really interesting, because not all strikes are created equal. The process I just described is for a standard circulation coin—the kind you find in your pocket. They're built for speed and durability.

A collector-grade proof coin, on the other hand, gets the VIP treatment.

A proof coin is the absolute pinnacle of the minting art form. It represents the best possible strike, designed to showcase the coin's design in perfect, flawless detail. The secret lies in striking the coin multiple times, but at a lower speed and with less intense pressure.

This multi-strike approach ensures the metal flows into every last nook and cranny of the die, creating exceptionally sharp, well-defined features. The blanks for proof coins are also specially prepared, polished to a mirror-like shine before they even see the press. This is what creates that classic cameo effect that collectors adore: frosted, matte-like designs that seem to float on a flawless, reflective background.

A quick comparison really shows the difference between making coins for everyone and crafting them for collectors.

Circulation vs Proof Coins: A Collector's Comparison

This table breaks down the key differences in how a standard coin and a collector's proof coin are made, which directly impacts how they look and feel.

| Feature | Circulation Coin | Proof Coin |

|---|---|---|

| Number of Strikes | Single strike at high speed | Multiple (at least two) strikes at low speed |

| Die Preparation | Standard working dies | Specially polished and treated dies |

| Blank Finish | Standard polished finish | Highly polished, mirror-like finish |

| Final Appearance | Standard lustre, designed for wear | Frosted design on a mirrored field (cameo) |

| Handling | Handled by automated machines | Handled individually by gloved operators |

Understanding these distinctions is key to appreciating why proof coins command a premium and are so sought-after in the numismatic world.

Once struck, the brand-new coin is ejected from the press. From there, it moves on to the final stage of its journey: a rigorous quality control inspection before it's cleared to enter circulation or be sealed into a collector's set.

Ensuring Perfection with Quality Control

A coin isn't truly finished the moment it drops from the coining press. The final, critical stage in understanding how coins are made is the rigorous quality control process that follows. This is the mint's promise that every single piece, whether it’s destined for a shop till or a collector’s display case, meets the exacting standards of The Royal Mint.

A coin isn't truly finished the moment it drops from the coining press. The final, critical stage in understanding how coins are made is the rigorous quality control process that follows. This is the mint's promise that every single piece, whether it’s destined for a shop till or a collector’s display case, meets the exacting standards of The Royal Mint.

For the coins you find in your change, the inspection process is a marvel of modern automation. High-speed cameras and sophisticated sensors scan every single coin that tumbles off the production line. These systems are programmed to spot even the most minute flaws.

Any coin with a slight blemish, a weak strike, or an off-centre design is instantly flagged and automatically rejected. This high-tech vigilance guarantees the consistency and quality we expect from our national currency, pulling any imperfect specimens long before they could ever reach circulation.

Special Handling for Collector Coins

The approach shifts gear entirely for special collector editions, like proof and brilliant uncirculated coins. Here, automation gives way to meticulous human care. These coins are handled individually by operators wearing soft cotton gloves, a simple but vital step to prevent fingerprints or scratches from marring their pristine surfaces.

For a collector, the condition of a coin is paramount. Proof coins, with their delicate, mirror-like fields and frosted designs, require this special handling to preserve the flawless finish created during the multi-strike process. This careful, hands-on approach is what separates a standard currency piece from a numismatic work of art.

After their individual inspection, these premium coins are carefully placed into their protective capsules and presentation packaging, ready to be dispatched to collectors around the world.

Final Steps: Counting and Bagging

Once both circulation and collector coins pass their respective inspections, they move on to the final logistical steps. Circulation coins are funnelled into automated counting machines which verify the exact quantities before channelling them into large, durable bags.

Each bag is securely sealed and clearly labelled with its denomination and total value—often containing thousands of pounds worth of new currency. From there, they are prepared for secure, armoured transport to banks and cash distribution centres across the UK.

This entire final stage, from inspection to bagging, is the unseen but vital guarantee of quality behind every coin you hold. It completes the coin's journey from raw metal to trusted currency, ready to enter the nation's economic bloodstream.

How Mintage Figures Create Collector Value

We've covered how a coin is physically made, but that doesn't explain why one 50p in your pocket is worth exactly that, while another might sell for hundreds of pounds. The secret is a concept every collector needs to master: mintage. It’s simply the total number of coins of a certain design that were ever produced, and it's the number one driver of scarcity and value.

Every time The Royal Mint strikes a coin, it eventually publishes the official mintage figures. These numbers tell you one of two stories. You’ve got your circulating coins, the ones made by the tens of millions to keep the economy moving. Then you have the special collector editions, where the production is deliberately kept low.

It’s this planned scarcity that transforms a piece of metal into a genuine collectable. A low mintage means fewer coins to go around for the millions of people who might want one. This creates a classic supply-and-demand situation that can really drive up the price on the secondary market.

From Circulation Finds to Bullion Coins

A brilliant real-world example is the famous 2009 Kew Gardens 50p. With a mintage of only 210,000, it’s the rarest 50p you can find in your change. To put that in perspective, the 2017 Sir Isaac Newton 50p had a mintage of 1.8 million, and the 2019 Sherlock Holmes 50p had over 8.6 million struck. That tiny production run for the Kew Gardens coin is what makes it a modern treasure.

This idea isn’t just for circulating coins; it’s even more critical for precious metal editions. The Royal Mint regularly issues limited-edition gold and silver coins aimed squarely at collectors and investors, where the mintage is a huge part of the appeal from day one.

For a collector, the mintage figure is more than just a number; it’s a direct indicator of a coin's future rarity. Learning to read and interpret this data is a fundamental skill for spotting coins with long-term growth potential and building a valuable collection.

Lately, The Royal Mint has been focusing more on these limited-mintage pieces, like the prestigious gold Sovereign. For example, the upcoming 2025 gold proof Sovereign sets have some very low numbers, with one particular presentation limited to just 7,025 coins. That's a big drop from the 7,500 issued in 2024 and less than half of the 15,000 struck in 2023. You can read more about the latest Sovereign mintage figures and their implications for your own collection.

Reading the Data to Spot a Rarity

Once you start paying attention to these figures, it changes how you look at every coin. It connects the industrial process of how coins are made to the thrill of numismatics. By keeping an eye on The Royal Mint's data, you can start to:

- Pinpoint which new commemorative coins have low production runs right from the start.

- Recognise potentially valuable coins that might just show up in your change.

- Make much smarter decisions when you're buying coins for your collection.

This knowledge turns collecting from a game of luck into a strategic hobby. For more hands-on advice, have a look at our guide on the seven tips for buying collectable coins to help you get started with confidence.

Frequently Asked Questions About Coin Making

Even after walking through the entire minting journey, a few questions often pop up about the finer details. For the curious collector, here are some answers to the most common queries we hear about The Royal Mint and how it creates the nation's currency.

Getting into these specifics really deepens your appreciation for the craft, the materials, and the sheer scale of coin production in the UK.

What Metals Are UK Coins Made From?

The metallic makeup of UK coins is a fascinating science, all about balancing durability, cost, and appearance. They aren’t just lumps of a single metal; each one is a specific alloy or plated combination designed for its role.

- 1p and 2p Coins: These get their classic copper look from a copper plating over a steel core.

- 5p and 10p Coins: For a bit more resilience, these are made from nickel-plated steel.

- 20p and 50p Coins: Both of these iconic coins use a cupro-nickel alloy, which is a classic blend of copper and nickel.

- £1 Coin: The modern bimetallic pound coin has two parts: a gold-coloured nickel-brass outer ring and a silver-coloured, nickel-plated alloy centre.

- £2 Coin: Similarly, the £2 coin features a cupro-nickel outer ring that surrounds a nickel-brass inner disc.

How Long Does It Take To Make A Single Coin?

While the whole process from an artist's initial sketch to a coin entering circulation can take months, or even years, the physical act of creating one is incredibly fast. That moment of striking? It’s almost instant.

A modern high-speed coining press at The Royal Mint can hammer out up to 750 coins every single minute. This blistering pace means an individual coin is stamped in a tiny fraction of a second—a testament to the incredible efficiency needed for modern production.

This speed is absolutely essential for minting the millions of coins needed for day-to-day circulation. For collector-grade proof coins, however, the process is the complete opposite. It's deliberately slowed down, with each coin struck multiple times to achieve that flawless, mirror-like finish collectors prize.

Can I Visit The Royal Mint?

Absolutely, you can! For anyone truly fascinated by this process, The Royal Mint Experience in Llantrisant, Wales, is a must-see. It offers a brilliant behind-the-scenes peek at the real thing.

The guided factory tours let you witness the action up close, from seeing the raw blank discs to watching those powerful presses at work. Best of all, you even get the chance to strike your very own coin to take home—the perfect souvenir for any enthusiast.

At Cavalier Coins Ltd, we share your passion for the stories behind every coin. Whether you're looking for a rare mintage piece or a unique commemorative issue, explore our curated selection of coins and banknotes from around the world. Visit Cavalier Coins today to discover your next collection highlight.